Ecoseal Vinyl Sheet Piles: The Sustainable Solution for Modern Construction

- ESC Steel LLC

- Nov 15, 2024

- 5 min read

Updated: Mar 15

In today’s world, sustainability and durability are at the forefront of construction innovation. ESC Ecoseal Vinyl Sheet Piles offer an eco-friendly and efficient solution for a wide range of applications, from coastal protection to retaining walls. This articles explores the numerous benefits and uses of ESC Ecoseal Vinyl Sheet Piles, making them an ideal choice for modern construction projects.

What Are Ecoseal Vinyl Sheet Piles?

Ecoseal Vinyl Sheet Piles are engineered using high-quality polyvinyl chloride (PVC) to create robust and resilient barriers. These sheet piles are designed to withstand harsh environmental conditions and provide long-lasting protection against erosion and water damage. Their lightweight and flexible nature make them easy to install, reducing labor costs and project timelines.

Advantages of Ecoseal Product

INSTANT SAVINGS

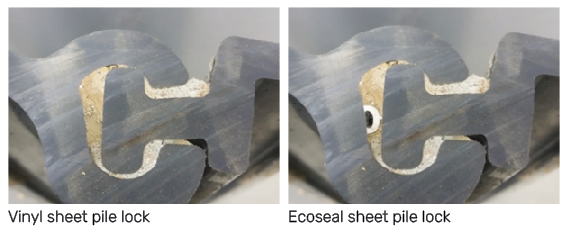

Traditional methods of sealing sheet pile locks require time-consuming and expensive procedures in the form of applying sealant inside the lock. Ecoseal provides savings on several levels, because the already water-tight product is delivered at site and is ready for installation.

IMMEDIATE WATERTIGHTNESS

Ecoseal sheet piles provide full watertightness immediately after installation. Unlike traditional methods, there is no need to wait for soil clogging in the locks or for the hardening of cement-soil mixtures.

CHEMICAL RESISTANCE

Ecoseal sheet piles are resistant to many chemicals, making them an ideal solution for environmentally sensitive areas where the migration of pollutants could pose a significant threat.

DURABILITY AND FLEXIBILITY

The gaskets, integrated during the post-co-extrusion process, become an integral part of the sheet piles, minimizing the risk of damage during installation and use. The flexibility of the material allows for precise adaptation to various soil conditions

ENVIRONMENTAL FRIENDLINESS

The use of vinyl and innovative gaskets reduces the need for steel and other conventional materials, which is both economically and environmentally beneficial. Ecoseal Vinyl Sheet Piles contribute to reducing CO2 emissions and support sustainable development by using recyclable materials and offering superior longevity compared to traditional steel sheet piles.

Steel sheet piles have a 207% to 807% higher environmental impact than PVC Sheet Piles. This analysis takes into account steel sheet piles without any coating.

Engineering Applications

TAILINGS DAMS

Ecoseal sheet piles are used in the construction of tailings dams to ensure the containment of mining waste materials. The integrated gasket technology provides a reliable seal that prevents the escape of toxic substances into the surrounding environment.

EVAPORATION PONDS FOR LITHIUM BRINE

In projects involving the extraction and processing of lithium brine, Ecoseal sheet piles are employed to construct evaporation ponds. These ponds require high levels of watertightness to efficiently manage the evaporation process and prevent the loss of valuable minerals.

PEATLAND APPLICATIONS

Peatlands are crucial for carbon storage and climate regulation. Ecoseal sheet piles are used to create impermeable barriers that maintain the natural water levels in peatlands, preventing their desiccation and subsequent release of greenhouse gases.

FLOOD CONTROL

Ecoseal has proven to be highly effective in flood control projects. The Ecoseal ensures that these barriers are watertight, offering reliable protection against rising water levels, protecting urban and rural áreas.

RESEARCH AND DEVELOPMENT

The Ecoseal technology has undergone rigorous laboratory and field tests to ensure quality and reliability. The laboratory testing procedure consists of a sample being placed in a special laboratory station, and then the sample is placed so that water can only get through the lock in the sheet pile. Then the process of pumping water takes place. The method requires constant measuring of the pressure on the pressure gauge. When leakage is observed on the dry side, the test is stopped and the result recorded.

Research conducted by the Institute of Fluid-Flow Machinery at the Lodz University of Technology in Europe confirmed that the watertightness parameter of gaskets passed a water-tightness test, which resulted in the issuance of a certificate confirming 100% tightness at the gasket interlocks.

Field Test of Ecoseal Vinyl Sheet Piles

Overview

To ensure the reliability and performance of Ecoseal vinyl sheet pile, a comprehensive field test was conducted. The objective was to validate the watertightness and structural integrity of Ecoseal under in situ conditions.

Test Procedure

Installation

A 40 lineal foot barrier was constructed using Ecoseal sheet piles 31 feet in length and driven into sandy soil.

Inspection

The barrier was excavated on both sides to a depth of 16 feet to visually inspect the interlocks, ensuring the performance and quality of the integrated gaskets.

Watertightness Test

One side was filled with water mixed with red dye to create hydraulic pressure equivalent to an 8-foot water column, testing for any leakage.

Results

No water leakage was observed, confirming the immediate and complete watertightness of the integrated gaskets.

Structural Integrity

The sheet piles maintained their structural integrity, with no signs of deformation or damage.

Conclusion

The field test validated the effectiveness of Ecoseal vinyl sheet piles, demonstrating their suitability for various hydrotechnical and environmental protection projects by ensuring reliable watertightness and structural durability in challenging conditions.

Problems Solved by Ecoseal

The piping effect is a process in which water under pressure penetrates the soil, causing erosion and weakening the embankment structure.

Ecoseal sheet piles prevent this phenomenon through their innovative design:

Watertightness:

The integrated soft PVC gasket eliminates filtration paths, preventing the piping effect. As a result, hydrotechnical structures equipped with Ecoseal are less susceptible to damage caused by erosion and soil particle migration.

Durability:

Ecoseal is durable and resistant to various soil and water conditions, making it an ideal solution for projects such as sealing flood levees, constructing dams, and creating cut-off walls.

Control of Seepage and Groundwater Flow

Ecoseal vinyl sheet piles are highly effective in controlling seepage and groundwater flow, providing reliable barriers that prevent unwanted water migration:

Seepage Control:

Ecoseal’s watertight connections ensure that seepage is stopped, protecting surrounding areas from potential water damage and contamination.

Groundwater Management:

By maintaining a stable groundwater level, Ecoseal helps preserve the integrity of natural and engineered structures, preventing issues such as subsidence, Peatland Desiccation and erosion.

Available Profiles Ecoseal

Here are the technical parameters of Ecoseal PESC-24-6.4 / 7.6 / 9.0 with: impact resistance, weight per wall, cap compatibility.

ESC ECOSEAL SHEET PILING WITH GASKETS (At client’s request)

Vinyl sheet pile profiles are manufactured with an integrated gasket, which ensures 100% water-tightness of the locks provided that they are properly installed.

Why Choose ESC Ecoseal Vinyl Sheet Piles?

ESC Ecoseal Vinyl Sheet Piles stand out due to their exceptional quality and performance. Manufactured using state-of-the-art technology, these sheet piles offer superior strength and durability. ESC's commitment to innovation and customer satisfaction ensures that you receive the best products for your construction needs.

For homeowners and contractors seeking a sustainable, durable, and cost-effective solution for their construction projects, ESC Ecoseal Vinyl Sheet Piles are the answer. From coastal protection to retaining walls, these vinyl sheet piles offer unmatched performance and environmental benefits. Choose ESC Ecoseal Vinyl Sheet Piles for your next project and experience the difference in quality and sustainability.

.png)